Hidden drainage gutter on corrugated roofing

Description of construction

A great popularity of architects nowadays is the use of concealed drainage troughs. This is a very interesting and effective solution, but it is very technically demanding and needs to be approached all the more responsibly. For one thing, the gutter is built into the façade of the building and any overflow of the gutter must be insured by a proper substructure and additional underfloor insulation and drainage membranes. I will be happy to base this on the drawings of Iuri Nushtaev, who has been working on this subject for a long time.

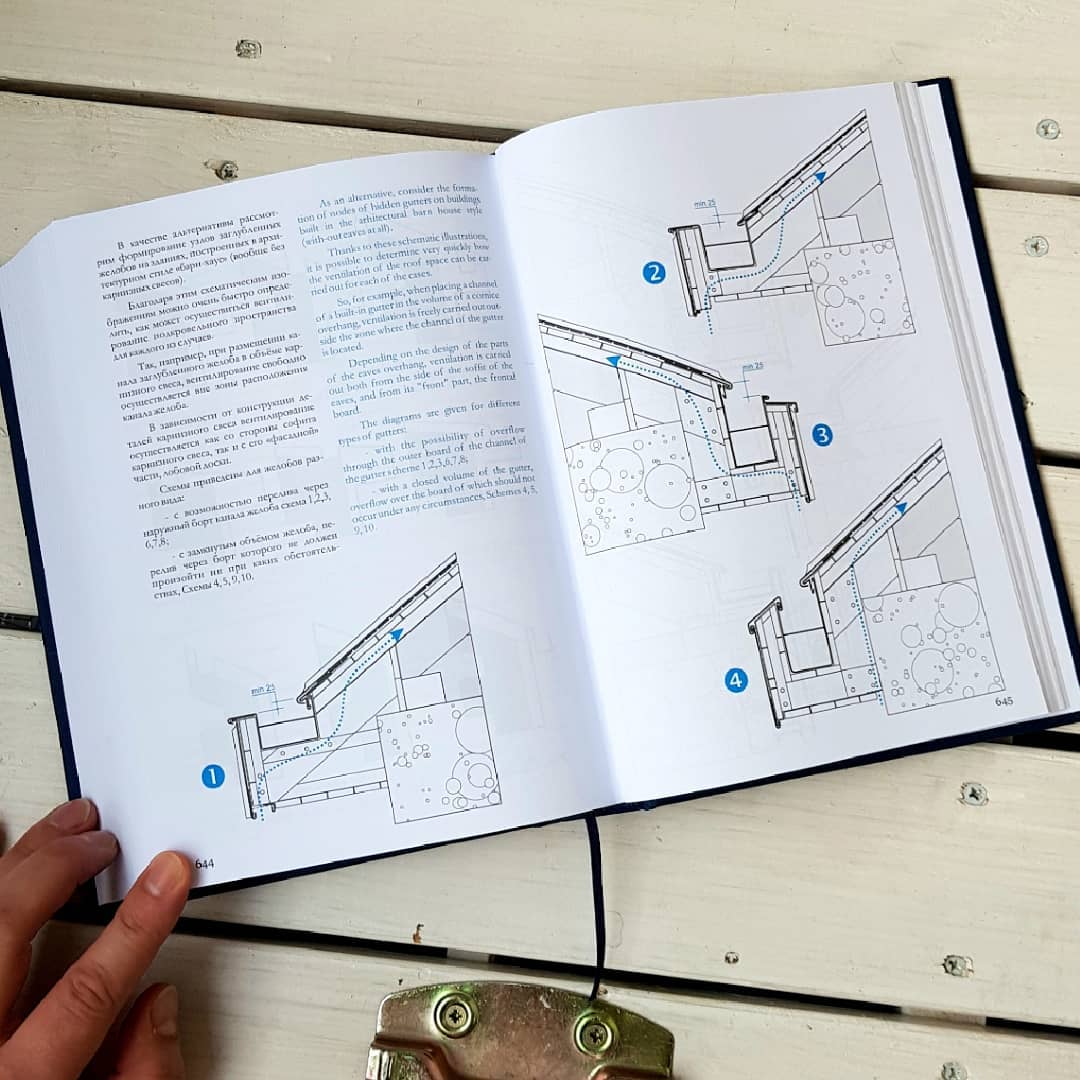

As is clear from the sketch, the design must also take into account the ventilation of both the roof and, of course, the façade it terminates. The course of the ventilation is shown by the dotted line in the previous figure. The details of the concealed gutter must include

- preparation of the underlying OSB or CETRIS boards

- application of base and drainage foil

- preparation of ventilation of the lower part of the trough

- installation of base plates for fixing the gutter

- fitting of the gutter prefabricated on a CNC bending machine

Plumber’s equipment

I certainly do not recommend working with this detail to plumbers who do not have the experience or proper plumbing tool equipment. To be sure, we’ll look at what tools you need to have

These are just a fraction of the tools that are needed, all hopefully in our e-shop in the plumbing tools section. Now let’s look at the details and the implementation of that detail. We will introduce the different types of designs used, based on Iuri Nushtaev’s book

- recessed gutter as part of the ventilated façade

- recessed gutter and transition between the contact insulation system

- recessed gutter as part of the roof

- recessed gutter as part of the cornice

When creating a hidden gutter, it is also necessary to choose the right material. From our point of view, the best materials are those that can be joined by soldering. Again, the requirement for the plumber is to have a good quality moulding machine with the correct moulding bodies and tools for clean and correct moulding. These are mainly the following material:

- copper plate

- titanium zinc

The construction can also be made of aluminium or steel nickel-plated sheet, but here the use of expansion strips and anti-creep material should be emphasized.

Inspiration

Since this is a modern feature and we don’t have that many references yet, I am attaching photos from Austria where it is already used more often.

Any questions and suggestions, please send us an email or just post in the footer of this article.