Cost savings in the production process in the plumbing workshop – our tips

At the beginning of 2021, the increase in the price of steel is obvious, which causes pressure on every manufacturing, assembly, and trading company. Therefore, cost savings are inevitable, especially in production inputs, to both speed up and streamline production or on-site assembly. Last but not least, a very interesting way to reduce these costs is also the recovery of waste or scrap sheet metal. In the following paragraphs I will list our view of the processes in each plumbing company where savings can be made and thus stabilise production costs. Production of perforated sheet metal and ventilation strips using a sign machine

– ventilation strips

– decorative holes in flashings

– gravel strips More information can be found here.

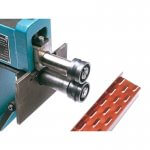

2. Preparation of plumbing elements and their profiling using signing wheels

More information here. 3. Bending facade cassettes (MARCUS templates)

– standing groove

– click system More information here.

4. Preparation of sheets for chimney sheeting in the workshop

More information here. 5. Die cutting

– AWG

– BK1

– V-CUT More information can be found here.

6. Production of K10-FH suffixes

More information here. 7. Warehouse process optimization

– coil rewinding

– stack storage More information here. 8. Making sills from better materials

– titanium zinc in different shades

– copper

9. New services offered to customers

– rewinding

– slitting

– cross slitting

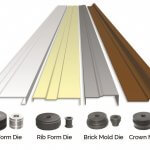

– sheet metal foiling More information here. 8. CNC bending

– stack of standardized mouldings

– new products in the production process More information can be found here.

I firmly believe that our solutions will inspire you to look for cost reductions in production and we will be glad if you contact us.