An important part of any façade is the use of plumbing elements on the façade and roof of the building. Due to the extension of thermal insulation made of glass wool and the insulation of buildings with the system of ventilated facades, the requirement for the necessary waterproofness and durability of plumbing elements is increasing. These must not only be of high quality and be built in, but above all be functional for the entire lifetime of the building work. In practice, the usual method of fixing these elements is by means of PU foam or other adhesives. When choosing the method, it is necessary to know the material from which these elements are manufactured. In this article we will take a closer look at the topic: the use and application of ENKOLIT.

Material of plumbing elements

- Galvanised sheet metal with lacoplast colour finish

- Aluminium sheet

- Titanium zinc

- Copper sheet

- Stainless steel

Structures

The following constructions can be made from the above materials:

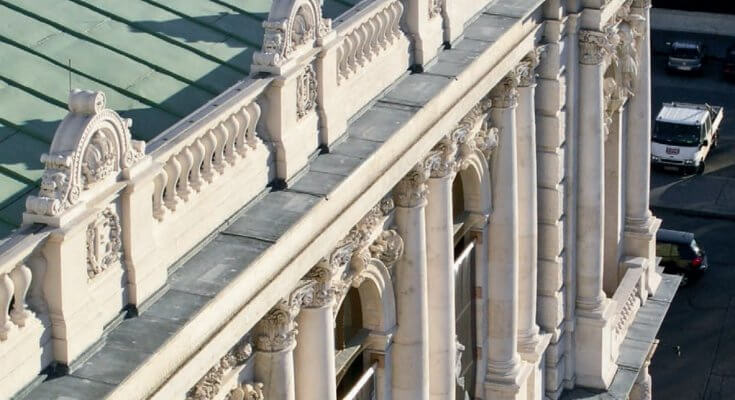

- cladding of dormers,

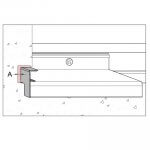

- manufacture of window sills,

- cladding of cornices,

- covering of concrete elements,

- cladding of attics,

- cladding of terraces.

Use and application of ENKOLIT

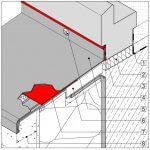

Application with ENKOLIT adhesive

The adhesive has the following basic functions:

- separation between the concrete and the plumbing element,

- bonding of elements,

- waterproofing and preventing rainwater from running into the facade,

- preventing condensation of water vapour on plumbing elements.

Tools needed:

- Spatula for ENKOLIT, size 250 mm,

- Spatula for ENKOLIT, medium 160 mm,

- Spatula for ENKOLIT, small 80 mm.

If you liked this article and are interested in any of the products listed, please visit our online store or send us an email.