Nowadays, every production process needs to be approached from the perspective of efficiency and also the use of the latest technologies. Therefore, the use of a CNC bending machine is only a minimum requirement. With this in mind and the creation of a new investment unit, we have created a framework diagram for the equipment of a standard plumbing workshop. Basically, it does not matter whether the bending machine will be CNC or not, the logic of the production process has to be considered.

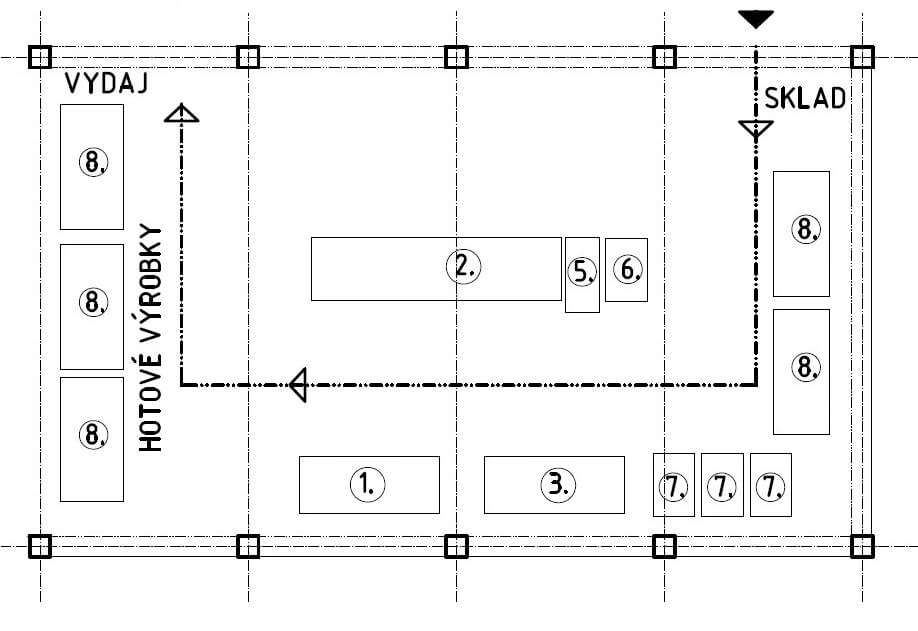

The layout of the plumbing workshop contemplates the following:

- the receipt of sheet metal in coil or plate form

- storage of input material

- handling and cutting of input material

- preparation and transfer for bending

- production of elements on the bending machine

- storage of new products and their storage

- dispatch of products

The JOUANEL CNC bender can be found at the following link.

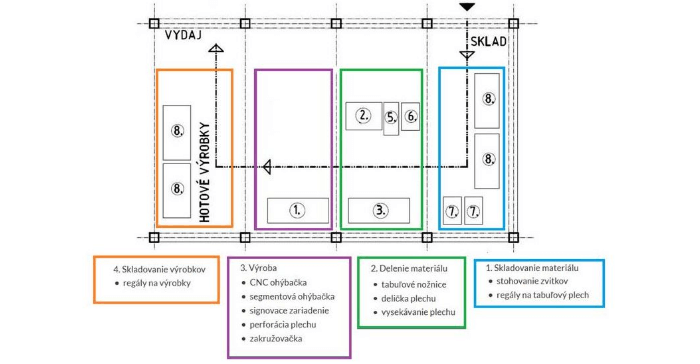

- Storage of material:

- stacking of coils,

- racks for sheet metal.

- Division of material:

- Plate scissors,

- sheet metal divider,

- sheet metal cutting.

- Production:

- CNC bending machine,

- segment bender,

- signalling device,

- perforation of the sheet metal,

- the curling iron.

- Storage of products:

- product racks.

- Expedition:

- handling of products,

- preparation for dispatch.

If you are continuously improving your business, buying a CNC bending machine is a natural step. Watch a few CNC bender videos to get a better idea of what these powerful machines can do.

The JOUANEL CNC bender can be found at the following link.

Before introducing CNC technology, it is also necessary to think about the incorporation of quality construction preparation and assembly work. I would put it into these steps:

- use of applications for precise construction orientation

- Leica 930 Digital Rangefinder

- preparation of the budget in CENKROS in the case of other offices

- Sema

- Viscon

- Cenkros

- Perfex

- Integration and interconnection of individual CNC devices

- CNC partition

- CNC profiling

- CNC bending machine

Expansion of production, higher efficiency, or the implementation of larger construction projects are all reasons that inevitably lead to the acquisition of a CNC bending machine. If you decide to expand your workshop equipment with this product, we will be glad if you contact us.

Schematic

- Input materials

- Division of material

- Production

- Storage of products