Facade cladding should always be ventilated

Particularly in the construction of buildings where the use of facade cladding is appropriate to obtain the desired effect, it is essential not to forget the building physics and the way the envelope structure behaves. The façade cladding will diffusionally close the perimeter wall and thus slow down or, in the worst case, stop the diffusion in the envelope. Simply put, moisture from the interior will not get through the cladding to the exterior and will get into the insulation between the cladding and the thermal insulation. Clearly, something is bound to get outside, but that moisture is created unnecessarily and might not when considering the elementary physical properties of envelope structures.

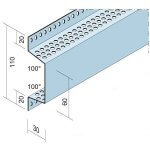

Use omega profile

It is necessary to anchor the façade cladding to the external wall of the building, provided that a ventilated gap is created. I like it better when mineral wool is used as thermal insulation behind the façade. It is more breathable and also has better thermal insulation properties. Nothing happens when you create a grid even when using polystyrene insulation. A wooden grid creates a certain thermal bridge, so it is better to use an aluminium grid on which you will fit the vertical lathing into which the facade cladding will be anchored.

Aeration is important

What is most important is to protect the resulting ventilation gap against the intrusion of insects or birds. To ensure ventilation, a ventilation grille should be placed at the bottom of the tiling and a vent at the top of the tiling to enclose the space and vent the air as well. It is this ventilation that will ensure the functionality of the cladding without creating unwanted moisture due to the lack of diffusion of the envelope. As ventilation grilles I recommend those that are aluminium and preferably with square perforations. More regarding ventilation grilles is covered in an article elsewhere. According to DIN 4308 part 3 (German standard for roofs) for a roof length of 10m the ventilation must not be less than 200 cm2/bm. In our conditions this means that the height of the contralate should be at least 6 cm. It is common to use a 5 cm height, but this is not such a big mistake.