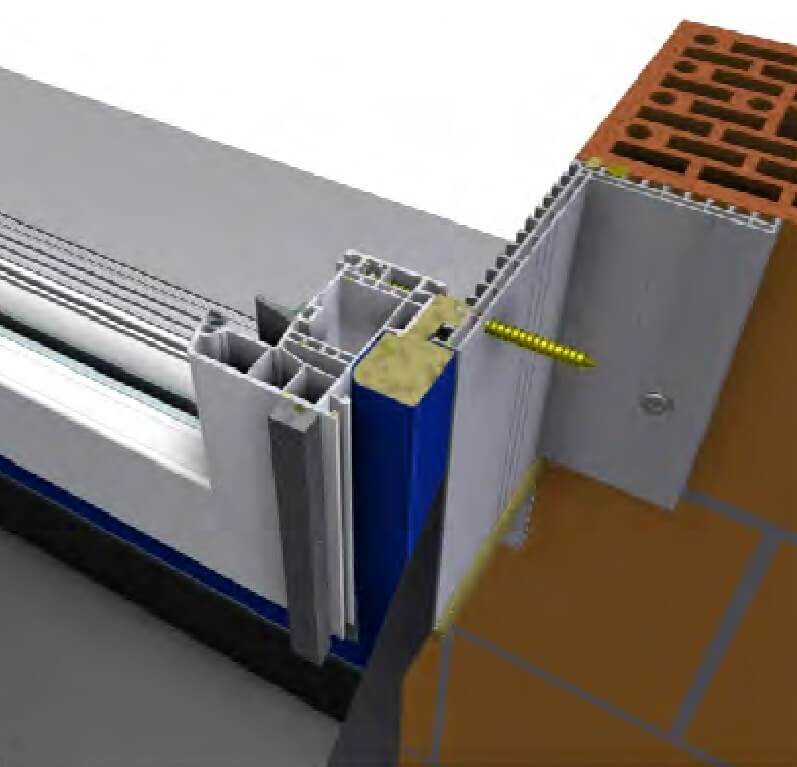

The fact that the thermal insulation of the perimeter structure has a greater thickness, the position of the window in the lining changes. Therefore, higher demands are placed on the installation of the window in terms of its position in the envelope. There are several ways of pre-setting the window. It is always necessary to take into account the thermo-technical characteristics of the solution. We prefer the following two types

- Pre-setting with PU boards

- Pre-setting with rigid static-bearing PVC L-profiles

In the case of a more detailed technical design, it is necessary to request from the designer his requirement for the placement of the window in the lining. According to this, the size and, of course, the method of anchoring the window will be determined. During this installation, it is of course necessary to ensure the connection of the window, the front structure and the perimeter masonry with a sealing system. This is particularly important in buildings with heat recovery and is a prerequisite in virtually every passive house. The main reason for this is that windows, even if they are of good quality, will always be the point of highest heat loss and so this needs to be taken into account. Another necessary technical issue is the construction of the guide rails in the case of the use of shading technology. The design must be such that it does not create an additional thermal bridge in the envelope. Ideally, aluminium or rigid PVC profiles should be used. The supplier of the shading technology should be informed of this requirement in order to find the most suitable solution.