Recently, architects have been making great use of the great variability of alucobond panels on the facades of buildings. The facade made of alucobond boards allows the use of various creative elements, which you can see in our gallery. It was created by observing new buildings in our area, which only confirms that these facades have great potential, especially in the area of multifunctional buildings.

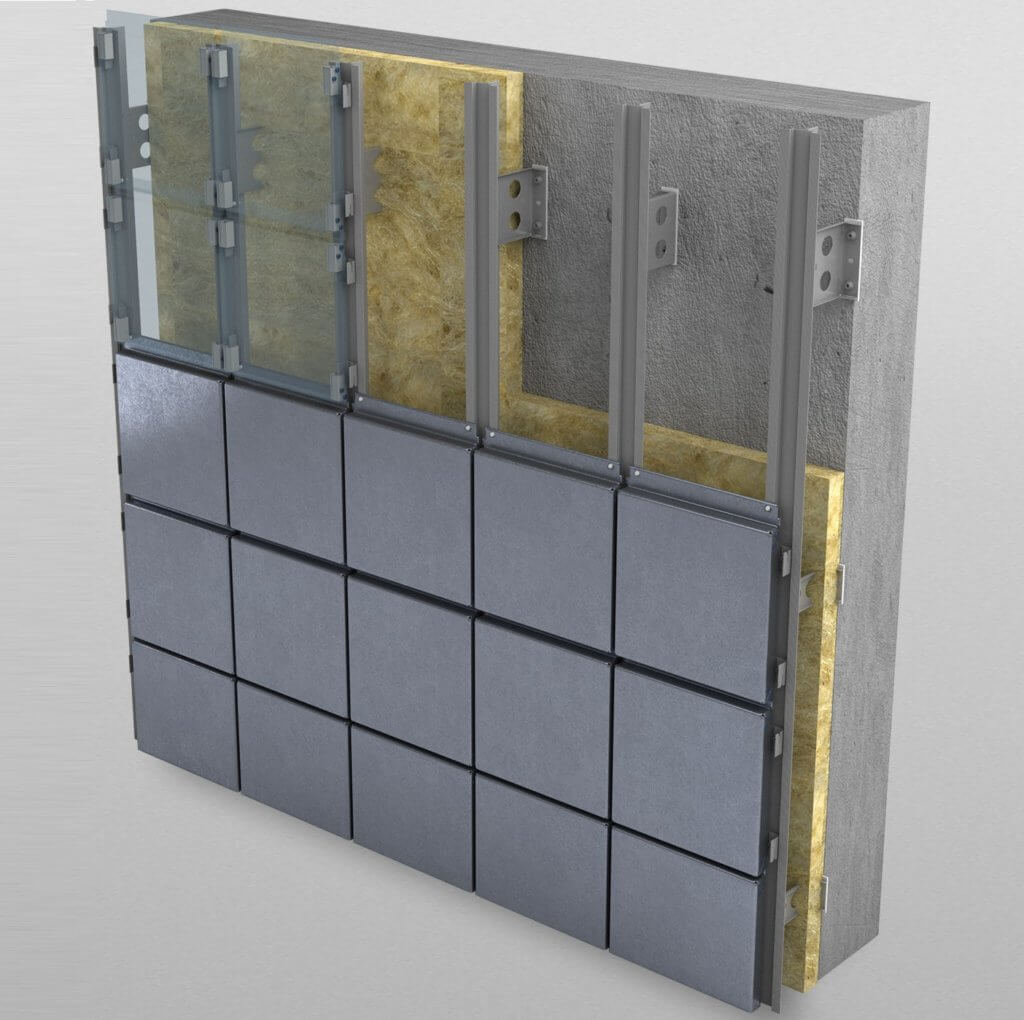

The boards are manufactured for each building separately and therefore any cassettes can be produced. It depends only on the imagination of the architect and the technological equipment of the facade contractor. There is a need for precise technology for the production of individual cassettes and these are usually already produced only thanks to CNC technology. The individual cassettes can be anchored to the subfloor grid using pre-milled fixings or, alternatively, by means of system fixings to the omega profile. We are reviewing this particular anchoring system because we see many advantages here. In particular, it saves time when installing the façade.

For milling and storage instructions for ALUCOBOND, please refer directly to the manufacturer’s website at this link. Formatting is possible with a large format CNC machine or with a flush saw from FESTOOL or another manufacturer. There are also several methods from FESTOOL, such as top milling. In any case, as the volume of orders increases, you will think more about CNC large format equipment. Nowadays, efficiency and minimizing workers in manufacturing is a big trend that you can’t avoid either.

Nevertheless, we will show you a short video where you will see how to mill with a FESTOOL saw or a top milling cutter.

The facade of alucobond boards is currently considered one of the most modern solutions, so do not hesitate to contact us by e-mail or phone and we will be happy to answer your questions.